Metal dimensions and long cans that are produced in geometrical sections from malleable steel sheets are called profiles.

Types of profiles

A: Open profiles include beams, belts, corners, studs, rebars.

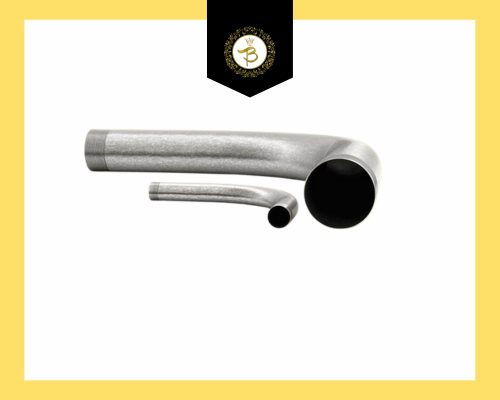

B: Closed profile includes tube and can (square-rectangle).

Application of the profile

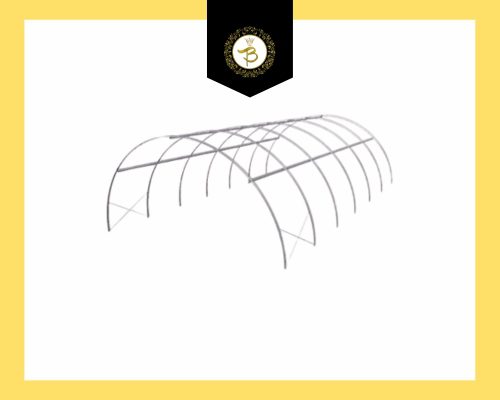

The profile has many uses in construction, industry and road construction, but its most use is in the manufacture of iron doors and windows. There are square and rectangular profiles, which are used in small sections for metal fences for doors and windows, staircases, factory walls, sidewalks, and streets, but the larger sections of the profiles are known as columns. are used in the construction of columns and metal frameworks.

Other uses of the profile

In the automotive industry

In making table and chair bases

The z type is for covering the roof of sheds

Making large iron door frames using corner profiles

Making shop shutters using stud profile

How to produce a type of square profile

The production of construction profiles and cans is done in 2 direct and indirect ways (the same as pipe production and conversion to the final shape), each of which has advantages and disadvantages.

1- Direct production method

In the direct production method, the strip is gradually formed by passing between the upper and lower molds (with a drive) and next to the idlers, which the designer has calculated in terms of the amount of force and the angles of the desired shape, which he has designed by distribution in each gate. After the two edges of the sheet are welded by frequency welding, it finally takes a complete shape in the sizing section.

The profile produced due to the application of force by the molds and welding heat is not completely straight and is corrected by the twister by re-applying force, bending, twisting and buckling. The profile being produced is cut by an automatic saw at 66-meter intervals and packed in a certain number and after installing the specification card and confirming the quality control, it is transferred to the product warehouse.

Advantages and disadvantages

The profile produced by the direct method is of higher quality and has sharp angles, precise dimensions and a fixed welding line on the upper wall and has a small surface curvature.

In this method, due to the sharp corner and the difference in the diameter of different points of the molds and the different linear speed, the depreciation of the molds is higher. Also, in terms of machining and heat treatment, more precision is necessary, on the other hand, more air space between the inductor and profile and ferrite will reduce the production speed and it will have a lower speed and lower efficiency compared to the indirect method.

2- Indirect production method

In this method, the profile is first converted into a pipe in the main rolling machine according to the above steps and one of the three bending methods, and after welding the two edges, in the sizing and twisting part, due to the upper, lower and side pressures, this pipe becomes Different shapes are converted or more complete in the sizing and twisting section of the pipe and the final product is produced and packaged after cutting.

Advantages and disadvantages

In this method, since it is possible to make a tube in the forming part and replace at least a few molds in the sizing part or take it to other non-welding devices, you can prepare several types of profiles. It is possible to have diversity with minimal pipe making machines. In addition, because the air gap between the inductor and the pipe is as small as possible and the selected diameter can be as high as possible, the maximum power of the welding machine can be used and the production speed will be higher than the direct method.

The molds have a curved shape and are easier to make with the machine, and in heat treatment, the probability of breaking is much less due to the absence of sharp corners, but in terms of quality, the corners are rounder and the size of the sides and welding line and surface curvature are less accurate than the method It will be direct

Application of various profiles

Square and rectangular profiles with small sections are used as metal fences for doors and windows of houses, the side of stairs, as well as fencing around the walls of factories and fenced areas, and fences for sidewalks and streets.

Square and rectangular (box) profiles with larger sections, which are known as columns, have many uses in industry and construction. These profiles, which are made in square sections, and their thickness ranges from 1.5 to 8 mm, can They are used in building columns and metal frames of buildings. Also, if these profiles are made with reliable physical specifications, they can be used in making the chassis of trailers and tankers.

Square and rectangular can profiles are also used in the automotive industry.

Square can profiles are also used in making table and chair bases.

Z-shaped profiles are mostly used to cover shed roofs.