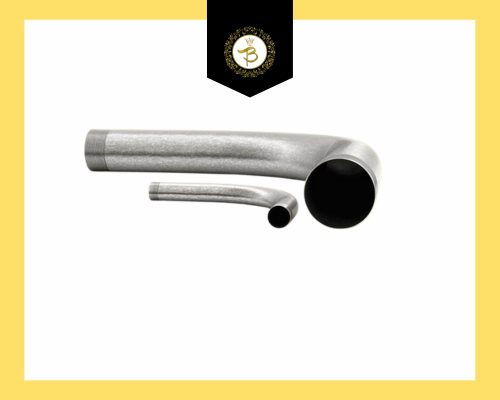

Cold drawing is one of the most important methods of producing furniture or light pipes. As mentioned, these pipes have the ability to stretch and bend. In the stretching method, the pipe sections are changed by passing through special molds. These templates are called stretch dose.

In this method, first a mold called Doze is made, whose inner hole is in the shape of the requested cross-section, and then the pipes are first suppressed and then passed through this mold by a tension device, and this changes the cross-section of the pipe or profile.

The important point is that stretching is one of the cold working processes, and as a result, it increases the bending strength of the furniture tube or profile. Therefore, it is sometimes necessary to use heat treatment as a complementary process in order to achieve the desired properties of the piece.

In the cold drawing industry, in comparison with other processes of forming sections, we can count some features:

1- Excellent surface quality

2- Accurate corners

3- Optimal dimensional accuracy

4- Reducing production costs

5- Less energy consumption

6- Faster production in less time

Other common methods of producing seamless and light pipes are:

• Pilger rolling method

• Pressure rolling method

• Rolling method on the cap

• Continuous rolling method with mandrel

• Rolling method without using mandrel

Now you can contact Bahnia sales group if you want to discuss with our sales and production staff about the production method of furniture tube or your special needs. We are waiting and ready to answer: 021 62719